Baypark Conveyance Project

Location

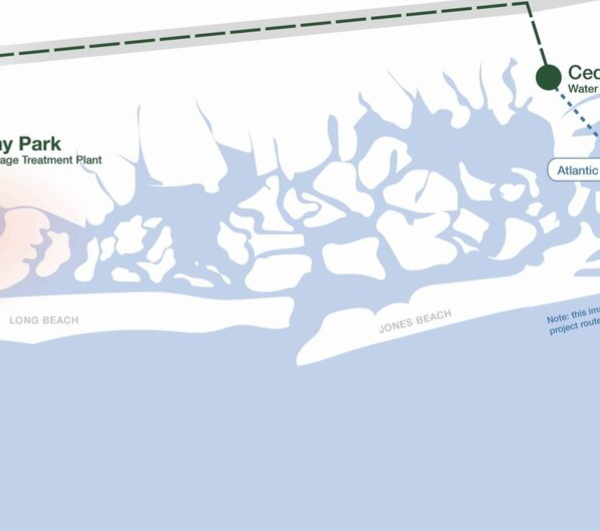

Bay Park to Cedar Creek NY

Client

Western Bays Constructors

Oversight Engineer

John P. Picone

Project Date

September 2021

Summary

- Two (2) mile of 90" force main from Bay Park Sewage Treatment to the county owned Aqueduct under Sunrise Hwy using a tunnel boring machine.

- Rehab/Reline 7.3 mile stretch of abandoned aqueduct

- 1.6 miles of 90" force main from the aqueduct to the exisiting Cedar Creek water pollution control plant's outfall pipe using a tunnel boring machine.

- Multiple entry and exit shafts constructed throughout the project for the TBM launch and landing.

- Slurry was designed specifically to meet the demands of the formation encountered.

Overview

Microtunneling will construct tunnels for a new pipeline deep below the surface from the South Shore Water Reclamation Facility (WRF) extending two miles north to the Sunrise Highway and from Sunrise Highway in western Wantagh extending over one and half miles south to the Cedar Creek Water Pollution Control Plant (WPCP). This approach minimizes surface disturbance to the surrounding communities and allows the project to advance in multiple locations simultaneously accelerating construction.

In total the Bay Park Conveyance Project will construct 10.9 Miles of new pipeline to convey treated water from the South Shore WRF to the Cedar Creek WPCP to be discharged through an existing ocean outfall.

Microtunneling will begin using 14 shaft locations in Bay Park. Shafts along the microtunneling corridor are being constructed to provide deep access points where microtunneling will advance. This construction technique is a safe, effective way to install piping deep into the ground, avoiding long trenches and surface disturbance. Notice to proceed was provided in March 2021 and groundbreaking in April 2021. The first launch of the MTBM occurred in April 2022.

What made this Complex

Due to the formation being so close to water sources and the bay, fluids had to be designed to minimize water exfiltration and infiltration while carrying a very high solid content back to the surface. Sentinel’s Holtsville, NY location was well situated to shorten the supply chain to the project. Understanding the need for bentonite in the heavy sand formation, we are using Super Sacks of bentonite along with a recipe of polymers to minimize the viscosity while generating very high yield points and gel strengths ensuring we successfully deliver the excavated material to the surface. Using various polymers along with the bentonite mixture, Sentinel’s fluids are keeping water losses/gains to a minimum and ensuring the Slurry Treatment plant is able to process the material and produce a dry stackable solid.

Due to many of the MTBM drives being very long, 1,400′ to 2,000′, Sentinel has also engineered the lubrication slurry which is injected through the pipe into the annulus. This slurry is critical to provide lubricity and reduced jacking pressures during the process. Here, we are using a lower yielding bentonite along with a suite of polymers.

The project has only recently begun and Sentinel’s drilling fluid engineers will make formation specific adjustments throughout the projects to maintain rheological properties best suited the project goals. Updates will be added as we move along.

How Sentinel Solved It

Videos

- Bay Park Conveyance - April 2022